Concrete is the second-most consumed material on the planet besides water, and is the most abundant construction material by a wide margin. The modern definition of concrete is an encompassing term for the mixture of coarse aggregate (rock), fine aggregate (sand), and Portland cement binder that binds it all together when mixed with water. It’s widely known now that cement production accounts for 5-8% of the global CO2 emissions annually, and every pound of cement produced emits 0.9 lbs of CO2 equivalent. A lot of the discussion and innovation around decarbonizing concrete is focused primarily on decarbonizing Portland cement manufacturing, or using an alternative binder altogether. The often overlooked impact of concrete use is the dwindling supply of construction grade sand, and the increasing costs to mine and freight this material. High quality aggregate is primarily found in riverbeds and lakes where thousands of years of erosion and attrition create a unique size and shape perfectly suited for concrete. Although it seems like there is an unlimited supply, sand from deserts and beaches that has been eroded by wind is not suitable for high quality concrete due to its uniform and spherical shape. Even though it is a naturally regenerating material our rate of consumption outpaces the rate of renewal. As supply struggles to match demand we are forced to import from further distances, and use more impactful means of mining. The cost of sand has tripled since 1990 from $3/ton to $9/ton, and prices are expected to double again over the next 40 years with rapid global industrialization.

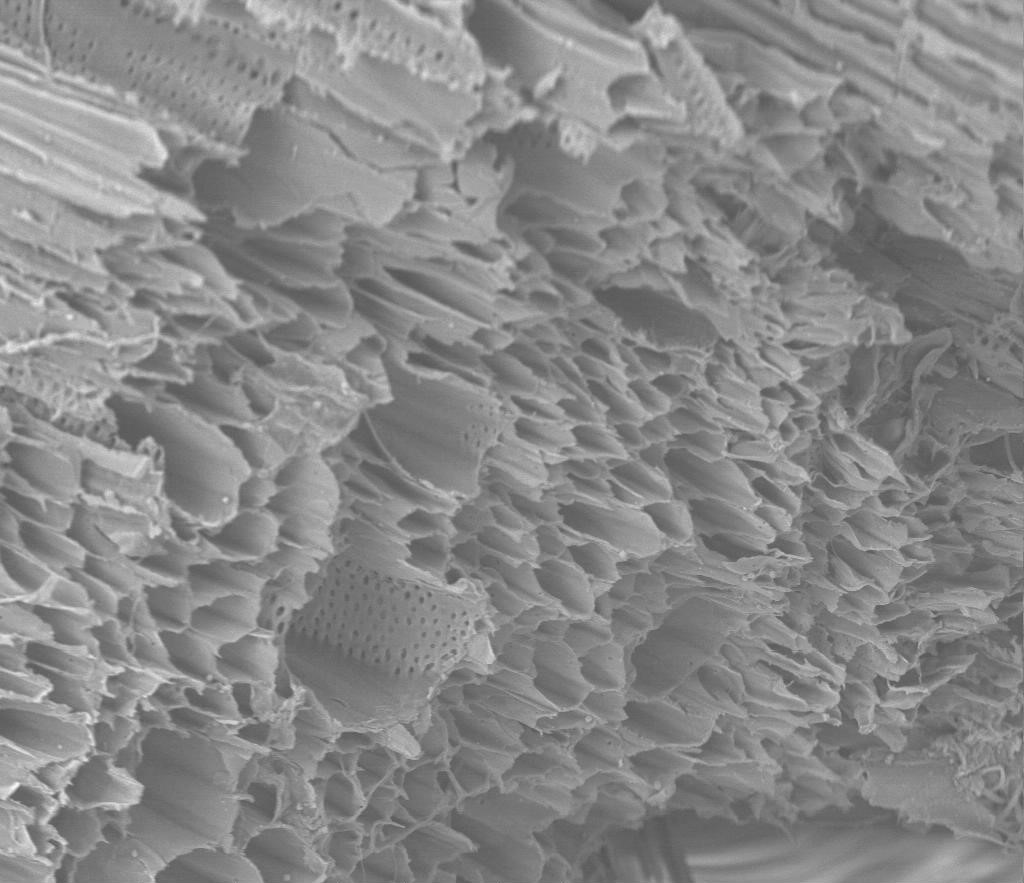

At Down to Earth Materials, a bioaggregate is a plant based fiber that is a renewable and carbon capturing supplemental material to sand. Utilizing our patented ClearWash™ process, we produce this novel material to reduce the overall carbon footprint of concrete, and keep pace with its increasing global demand.